All Info Share

-

AG glass parameter List

.png) ,

,

Except these parameters, there are “Sparkling” which belongs to end-user’s subjective identification for the glass visual appearance. The high/low gap between sparkling requirement depends on end-user display technique.

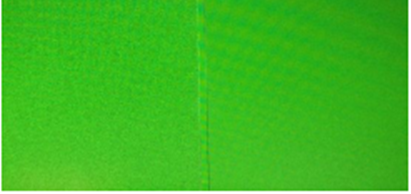

Ex. PPI resolution, like pixel density which means the high numbers represent display effect meticulous. However, it doesn’t mean sparkling low is the end-user requirement. It should match end-user display specification and demand to choose appropriate sparkling glass. (Below left: Sparkling high; below right: sparkling low)

Nowadays, thousands of vendor’s instruments can be claimed to detect sparking, however, after auto display T1 factory measured that even cannot beat the result of human’s eyes visual inspection. So GCM suggest pls provide “both side acceptable boundary sample” for future production reference.

GCM sparkling judgement rule: Iphone 6s, 1334x750 pixel, 326ppi green background, naked eyes observation.

-

Correlation between AG glass optical parameters and visual effects

As we known, semiconductor wafer parameters have absolutely correlation relationship with electricity. While glass material is different. Glass application mainly focus on exterior device appearance. End-user often choose their favorite glass by visual effects which is easily change their mind by personal subjective priority and backend display technique.

GCM etching processing skill, for example, under the same condition of GU80, GCM can process at least 3 different kinds of visual effects (light tube reflection most clarity, middle clarity and visual vague; the sparkling and roughness are different too). That’s the reason why GCM need to confirm again and again with end-user what’s their visual effects requirements.

-

AG glass processing sequence order

Processing sequence order: mother subtract -> AG etching processing-> tempered process -> following CNC/AR/AF/AS coating processing.

AG etching processing will be according with mother subtract size, thickness, final product size and its non-quality area. -

Will processed AG glass thickness reduction

YES! Pls take both mother subtract thickness and processed etching AG thickness reduction for consideration if the end-user concern thickness requirements.

Ex. Japan CG 1.8mm thickness mother subtract for in-coming quality assurance tolerance is 1.8±0.10mm. But the truth is quite majority in-coming mother subtract thickness toward lower limit which between 1.72~1.76mm, few thickness are >1.78mm.

If end-user choose etching AG to GU80, light tube middle clarity, Ra<0.15 option, after processed etching glass thickness will be reduced approximately 0.12~0.15mm. Estimated these toward lower limit CG mother subtract after etching processing, the final thickness range will be reduced to 1.595mm lowest ~1.655mm highest.

Definitely cannot meet the end-user final thickness requirement if 1.8±0.1mm. For this case, GCM will recommend etching processing glass final thickness tolerance is 1.7±0.15mm.

-

AG glass options and purchase guideline

- GCM can quote if end-user merely offer glass parameters?

INCORRECT! As item 4 mentioned that the same gloss conditions, GCM can offer several kinds of visual effects.

To proceed with proper procurement, GCM recommend pls provide the complete optical parameters and actual sample. GCM welcome you to contact with our sales window for require AG processed etching CD case for further AG processing confirmation.

Meanwhile, different types of mother subtract after etching processed which glass final visual appearance effects could be different. Ex. Japan brand: AS2 vs. CG, under the same GU80 conditions, AS2 visual appearance effects will be more clarity than CG. - End-user require “visual foggy AG”. Does it mean the etching AG processing parameters “Haze” is high?

INCORRECT! As Haze and visual foggy effect does not have absolutely correlation. As (1) explanation, GCM have to check the end-user actual sample first, then confirm optical demands & final visual appearance effects. Merely single optical parameter CANNOT be judged what’s the final visual result. - Extracted by customer message: “There’s a new developing project recently, we only have some limit optical data, need some time to figure out end-user actual optical specifications. Also have to match with currently technique or this newly developing display technique etc. Under this condition, how could we choose AG processing glass?”

GCM welcome you to visit us to advise your temporary optical specification (or bring actual sample), GCM will do our best to provide the professional experiences and sample bank to assist you the acquire most similar visual appearance asap.

- GCM can quote if end-user merely offer glass parameters?

-

GCM capacity and processing ability

Pls refer GCM company profile.